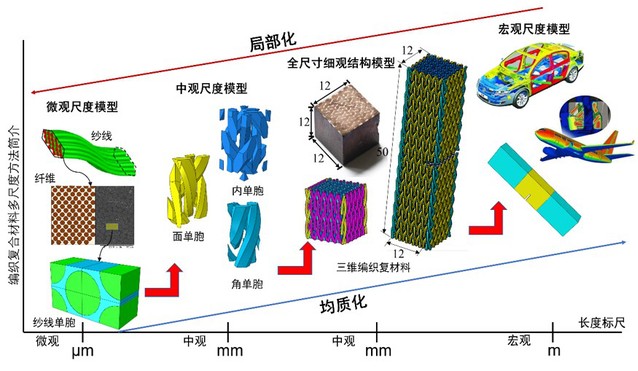

1 三维纺织复合材料多尺度几何模型和单胞子程序库

基于纺织复合材料多尺度几何结构特征,建立三维正交机织、三维针织间隔结构、三维多重混杂针织结构复合材料单胞模型库、UMAT/VUMAT子程序库、相关程序包;完善现有单胞模型,形成商用子程序库。扩展所有种类三维纺织复合材料子程序库,用于冲击加载和疲劳加载计算。

图1 多尺度几何模型

代表性论文:

1 He B, Mi ZX, Wang YJ, Gu BH. Unit cell modeling on torsion damage behavior of a novel 3-D integrated multilayer fabric reinforced composite tubular structures. Textile Research Journal, 2019, 89(19-20): 4253–4264.

2 Ouyang YW, Sun BZ, Gu BH. Finite element analyses on bending fatigue of three-dimensional five-directional braided composite T-beam with mixed unit-cell model. Journal of Composite Materials, 2018, 52(9): 1139–1154.

3 Wan YM, Sun BZ, Gu BH. Multi-scale structure modeling of damage behaviors of 3D orthogonal woven composite materials subject to quasi-static and high strain rate compressions. Mechanics of Materials, 2016(March), 94: 1-25.

4 Wan YM, Sun BZ, Gu BH. Multi-scale structure finite element analyses of damage behaviors of multi-axial warp-knitted composite materials subjected to quasi-static and high strain rate compressions. The Journal of the Textile Institute, 2016, 107(7): 879-904.

5 Li YY, Gan XH, Gu BH, Sun BZ. Dynamic responses and damage evolutions of four-step three-dimensional braided composites subjected to high strain rate punch shear loading. Journal of Composite Materials, 2016, 50(12): 1635-1650.

6 Jia XW, Xia ZH, Gu BH. Nonlinear numerical predictions of three-dimensional orthogonal woven composite under low-cycle tension using multiscale repeating unit cells. International Journal of Damage Mechanics, 2015, 24(3): 338-362.

7 Wan YM, Wang YJ, Gu BH. Finite element prediction of the impact compressive properties of three-dimensional braided composites using multi-scale model. Composite Structures, 2015(September), 128: 381-394.

8 Zhang F, Wan YM, Gu BH, Sun BZ. Impact compressive behavior and failure modes of four-step three-dimensional braided composites-based meso-structure model. International Journal of Damage Mechanics, 2015, 24(6): 805-827.

9 Wu LW, Gu BH, Sun BZ. Finite element analyses of four-step 3-D braided composite braided composite bending damage using repeating unit cell model. International Journal of Damage Mechanics, 2015, 24(1): 59–75.

10 Zhang F, Liu K, Wan YM, Jin LM, Gu BH, Sun BZ. Experimental and numerical analyses of the mechanical behaviors of three-dimensional orthogonal woven composites under compressive loadings with different strain rates. International Journal of Damage Mechanics, 2014, 23(5): 636-660.

11 Sun BZ, Pan H, Gu BH. Tensile impact damage behaviors of co-woven-knitted composite materials with a simplified microstructure model. Textile Research Journal, 2014, 84(16): 1742-1760.

12 Sun BZ, Wang JH, Wu LW, Fang F, Gu BH. Computational schemes on the bending fatigue deformation and damage of three-dimensional orthogonal woven composite materials. Computational Materials Science, 2014(August), 91: 91-101.

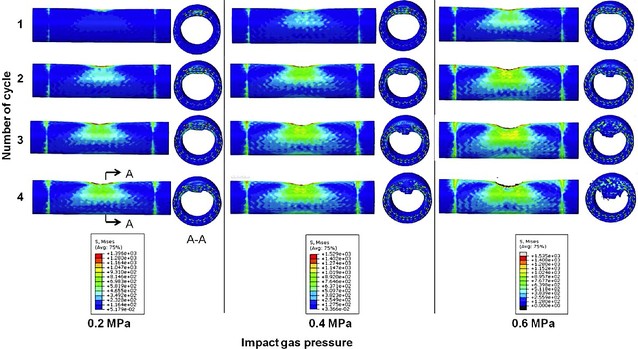

2 三维纺织复合材料工程结构力学性质应变率效应

研究常见三维纺织复合材料工程结构如T形梁、工字梁、圆管等在准静态和冲击加载下力学响应和失效机理,发现复合材料多尺度结构、工程结构件外形尺寸、复合材料力学性质应变率效应间协同效应。为轻质高强工程结构件设计提供系列设计原理和方法。

图2 三维编织复合材料冲击压缩载荷应变率效应

代表性论文:

1 Siddique A, Sun BZ, Gu BH*. Structural influences of two-dimensional and three-dimensional carbon/epoxy composites on mode I fracture toughness behaviors with rate effects on damage evolution. Journal of Industrial Textiles, 2020, 50(1): 23-45.

2 Liu T, Sun BZ, Gu BH. Size effects on compressive behaviors of three-dimensional braided composites under high strain rates. Journal of Composite Materials, 2018, 52(28): 3895–3908.

3 Zhou HL, Pan ZX, Gideon RK, Gu BH, Sun BZ. Experimental and numerical investigation of the transverse impact damage and deformation of 3-D circular braided composite tubes from meso-structure approach. Composites Part B, 2016, 86(February): 243-253.

4 Gideon R, Zhou HL, Wu XY, Sun BZ, Gu BH. Finite element analysis of 3D circular braided composites tube damage based on three unit cell models under axial compression loading. International Journal of Damage Mechanics, 2016, 25(4) 574–607.

5 Gideon R, Sun BZ, Gu BH. Quasi-static compression and compression–compression fatigue characteristics of 3D braided carbon/epoxy tube. The Journal of the Textile Institute, 2016, 107(7): 938-948.

6 Zhou HL, Sun BZ, Gu BH. Responses of 3D four-directional and five-directional circular braided composite tubes under transverse impact. International Journal of Crashworthiness, 2016, 21(4): 353 – 366.

7 Zhou HL, Zhang W, Liu T, Gu BH, Sun BZ. Finite element analyses on transverse impact behaviors of 3-D circular braided composite tubes with different braiding angles. Composites Part A, 2015, 79: 52-62.

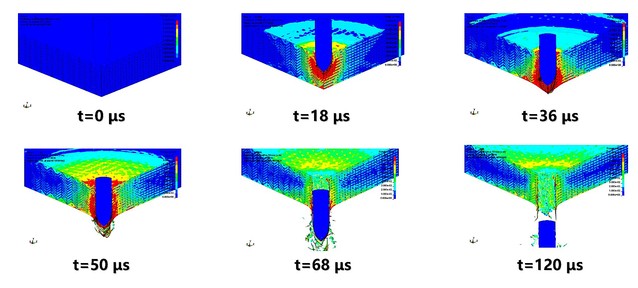

3 三维纺织复合材料弹道侵彻动力学

在连续介质、单胞结构和细观结构结构层面,用实验测试、分析模型和数值计算三种方法研究三维机织、编织和针织复合材料弹道侵彻破坏,形成关于三维纺织结构复合材料弹道侵彻破坏系统解释,应用于飞行器、高速车辆和防护装甲设计。

图3 弹道冲击破坏过程

图4 弹道冲击局部破坏过程

代表性论文:

1 Wei QS, Yang D, Gu BH, Sun BZ. Numerical and experimental investigation on 3D angle interlock woven fabric under ballistic impact. Composite Structures, 2021, 266: 113778.

2 Wei QS, Yang D, Gu BH, Sun BZ. Numerical analysis of strain rate effect on ballistic impact response of multilayer three-dimensional angle-interlock woven fabric. International Journal of Damage Mechanics, 2021, 30(6): 923-944.

3 Wei QS, Gu BH, Sun BZ. Ballistic penetration damages and energy absorptions of stacked cross-plied composite fabrics and laminated panels. International Journal of Damage Mechanics, 2020, 29(9): 1465-1484.

4 Luan K, Gu BH. Energy absorption of 3-D angle-interlock woven composite under ballistic penetration based on a multi-scale finite element model. International Journal of Damage Mechanics, 2015, 24(1): 3-20.

5 Luan K, Sun BZ, Gu BH. Ballistic impact damages of 3-D angle-interlock woven composites based on high strain rate constitutive equation of fiber tows. International Journal of Impact Engineering, 2013(July), 57: 145-158.

6 Zhu LT, Sun BZ, Hu H, Gu BH. Ballistic impact damage of biaxial multilayer knitted composite. Journal of Composite Materials, 2012, 46(5): 527-547.

7 Hou YQ, Sun BZ, Gu BH. An analytical model for the ballistic impact of three dimensional angle-interlock woven fabric penetrated by rigid cylindro-spherical projectile. Textile Research Journal, 2011, 81(12): 1287-1303.

8 Jia XW, Sun BZ, Gu BH. A numerical simulation on ballistic damage of 3-D orthogonal woven fabric. International Journal of Damage Mechanics, 2012, 21(2): 237-266.

9 Jia XW, Sun BZ, Gu BH. Ballistic penetration of conically cylindrical steel projectile into 3-D orthogonal woven composite: a finite element study. Journal of Composite Materials, 2011, 45(9): 965-987.

10 Shi WF, Hu H, Sun BZ, Gu BH. Energy absorption of 3D orthogonal woven fabric under ballistic penetration of hemispherical-cylindrical projectile. Journal of the Textile Institute, 2011, 102(10): 875-889.

11 Jin LM, Sun BZ, Gu BH. Finite element simulation of three-dimensional angle-interlock woven fabric undergoing ballistic impact. Journal of the Textile Institute, 2011, 102(11): 982-993.

12 Luan K, Sun BZ, Gu BH. A multi-scale geometrical model for finite element analyses of three-dimensional angle-interlock woven composite under ballistic penetration. CMES: Computer Modeling in Engineering & Sciences, 2011, 79(1): 31-62.

13 Li ZJ, Sun BZ, Gu BH. FEM simulation of 3D angle interlock woven composite under ballistic impact from unit cell approach. Computational Material Science, 2010, 49(1): 171-183.

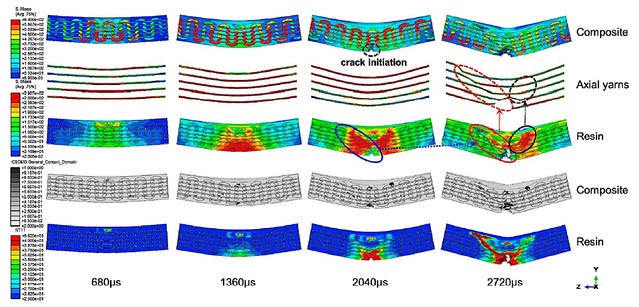

4 三维纺织复合材料冲击加载热力耦合效应

从纤维和基体热性质出发,基于纺织复合材料多尺度几何结构,发现在-150 ~ 500℃环境中复合材料在冲击/准静态加载下力学性质和破坏机理,形成三维纺织复合材料瞬态热力耦合在材料和几何结构层面上的解释。应用于在极端加载条件下纺织复合材料工程结构设计。

图5 3D5d编织复合材料在4个冲击循环下的损伤和温度演化规律

1 Hu MQ, Sun BZ, Gu BH. Microstructure modeling multiple transverse impact damages of 3-D braided composite based on thermo-mechanical coupling approach. Composites Part B, 2021, 214: 108741.

2 Zhang JJ, Zhang W, Huang SW, Gu BH. An experimental-numerical study on 3D angle-interlock woven composite under transverse impact at subzero temperatures. Composite Structures, 2021, 268: 113936.

3 Hu MQ, Liu SK, Zhang JJ, Wang L, Sun BZ, Gu BH*. Multiple transverse impact damage behaviors of 3-D braided composite beams under room and high temperatures. International Journal of Damage Mechanics, 2020, 29(5): 715–747.

4 Zhang JJ, Hu MQ, Liu SK, Wang L, Gu BH, Sun BZ. High strain rate compressive behaviors and adiabatic shear band localization of 3-D carbon/epoxy angle-interlock woven composites at different loading directions. Composite Structures, 2019 (March), 211: 502-521.

5 Wang HL, Sun BZ, Gu BH. Finite element analyses on longitudinal compressive behaviors of 3D braided carbon /epoxy composite with different braided angles at low temperatures. Journal of the Textile Institute, 2019, 110(1): 37-49.

6 Pan ZX, Sun BZ, Shim VPW, Gu BH. Transient heat generation and thermo-mechanical response of epoxy resin under adiabatic impact compressions. International Journal of Heat and Mass Transfer, 2016, 95: 874–889.

7 Dong K, Liu K, Zhang Q, Gu BH, Sun BZ. Experimental and numerical analyses on the thermal conductive behaviors of carbon fiber/epoxy plain woven composites. International Journal of Heat and Mass Transfer, 2016(November), 102: 501–517.

8 Dong K, Zhang JJ, Jin LM, Gu BH, Sun BZ. Multi-scale finite element analyses on the thermal conductive behaviors of 3D braided composites. Composite Structures, 2016(May), 143: 9-22.

9 Pan ZX, Sun BZ, Gu BH. Thermo-mechanical numerical modeling on impact compressive damage of 3-D braided composite materials under room and low temperatures. Aerospace Science and Technology, 2016, 54(July): 23-40.

10 Zhang W, Pan ZX, Gideon RK, Gu BH, Sun BZ. Effects of temperature and strain rate on impact compression behaviors of three-dimensional carbon fiber/epoxy braided composites. Journal of Composite Materials, 2015, 49(7): 771-782.

11 Pan ZX, Gu BH, Sun BZ. Longitudinal compressive behaviour of 3D braided composite under various temperatures and strain rates. Applied Physics A, 2015, 118(4): 1315-1337.

12 Pan ZX, Gu BH, Sun BZ. Thermo-mechanical behaviors of 3-D braided composite material subject to high strain rate compressions under different temperatures. Mechanics of Advanced Materials and Structures, 2016, 23(4): 385-401.

13 Pan ZX, Zhang Q, Gu BH, Sun BZ. Effect of temperature and strain rate on biaxial warp-knitted composite. Journal of Reinforced Plastics and Composites, 2016, 35(4): 295-304.